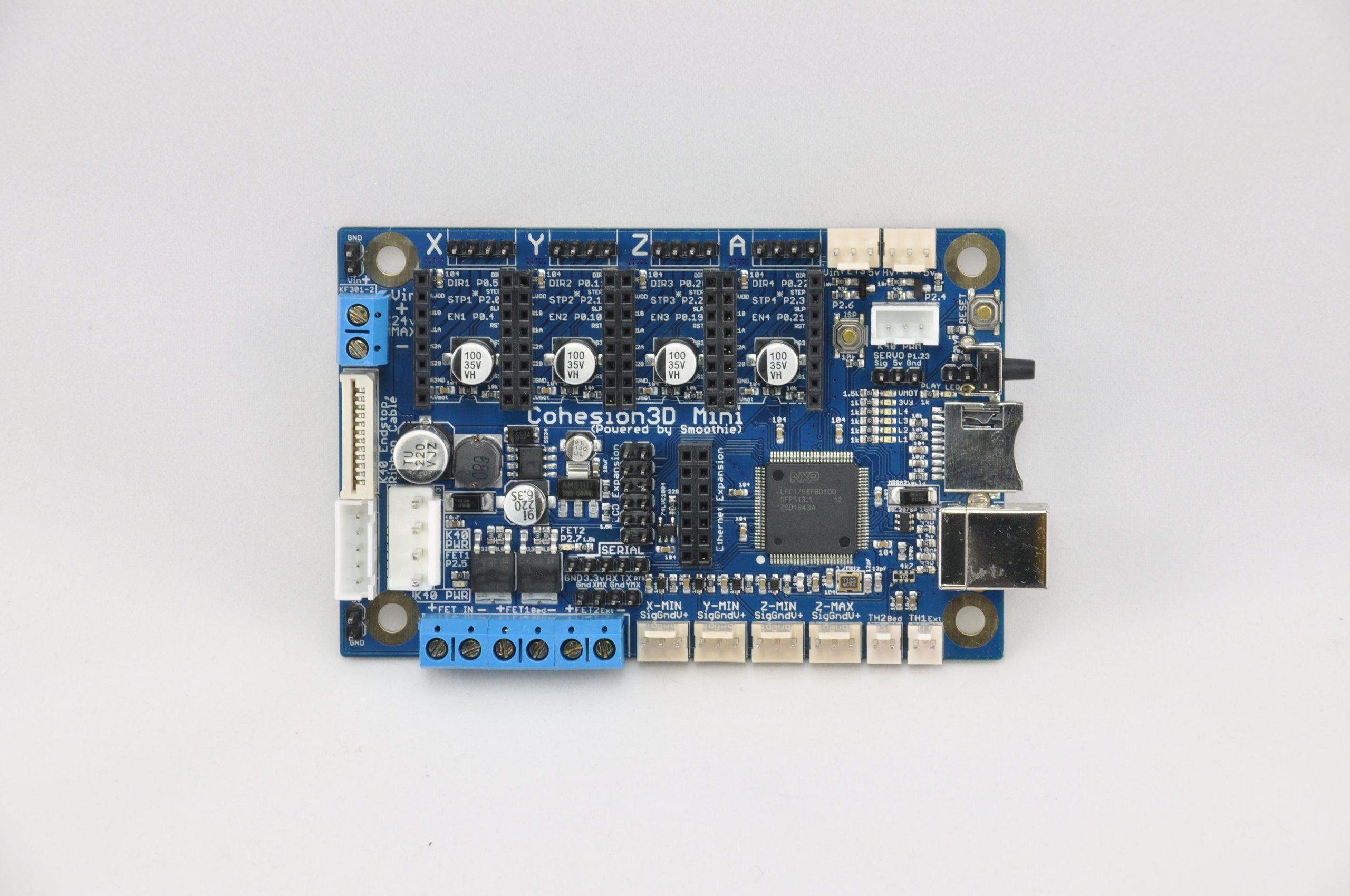

I then want to modify smoothieware to perform an action (I’ll likely begin with stopping, ) when it receives that signal on the gpio pin I choose. My interface board monitors the output of an LCR meter (HP4275 that will constantly read the resistance of a given part) then my board can output a digital signal (TTL 1, TTL 0, CMOS 1, or CMOS 0) when the reading reaches one of the values that are set on the interface board. The way I have planned to accomplish this is as follows Lightburn works perfect with this controller and you are set for advanced engravings and a better work flow than. Not sure if the details matter to you or not, but I am trying to trim resistors with a CO2 laser I built (cartesian K40 design using Cohesion3D controller). The Cohesion3d LaserBoard is one of the best upgrades regarding controller board for your laser machine. I need to have an input pin that can be triggered with a digital signal (TTL or CMOS, high or low, I have made the interface board flexible as to what it outputs) that will either immediately stop or, if possible, skip to the next cutting bank. I ask this as I am using the board in an unusual way and need to make the best decision of what/where to tap into. Caution: It may or may not apply depending on the parts you intend to buy and the model of K40 you are running.I am really looking for a list or a diagram of where each of the pins (from the ARM mcu) are broken out onto the board. When you decide what parts you want I(we) can help you create a wiring diagram so that you get the correct parts and wire them correctly.Īttached is a diagram for a similar supply conversion I helped someone else with. the “L” signal from the stock controller to the proper signal on the new LPS. Here is a diagram showing the pins used on the LaserBoard: Laserboard pinout or simplified schematic Hardware Installation We have not yet released a pinout diagram as we prefer to walk people through whatever they want to do and are happy to answer those questions. the new LPS into the chassis cable harness connected to the old LPS insuring that the coolant, laser switch and fire are all reconnected properly. The light object power/bed does work with the Cohesion3D laser board. the new 24V and 5V supplies to the stock controller card and insure the controller ground is tied to the the LPS ground the new LPS AC input and safety ground are wired correctly. I did however help someone else and I believe the new LPS handled the 5V ok. I do not know how safe it is to run the 5v from your new supply to the stock controller as I do not know the capacity of the new supplies 5V nor the load of the stock controller. You can run 2 external supplies: 24V in addition to your new LPS.

0 kommentar(er)

0 kommentar(er)